O-rings are indispensable components in sealing applications, valued for their affordability and versatility. This guide delves into their fundamental characteristics, selection considerations, optimal installation practices, and crucial maintenance tips to ensure peak performance.

1. Characteristics of O-Rings

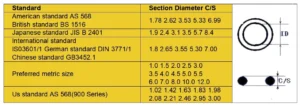

O-rings boast a unique sealing mechanism, offering automatic two-way action due to radial and axial pre-compression upon installation. Their performance parameters are governed by international standards like AS 568, JIS B 2401, and ISO 3601/1, ensuring consistency and compatibility across various applications.

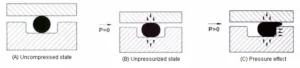

2. Sealing Mechanism

The O-ring serves as an automatic two-way action sealing element, employing a sophisticated mechanism to ensure effective sealing. Upon installation, it undergoes radial and axial pre-compression, harnessing its innate sealing prowess. As system pressure escalates, this sealing capacity amplifies, reinforcing its ability to withstand dynamic conditions and maintain a reliable seal.

3. Factors Influencing O-Ring Selection

Selecting the appropriate O-ring material requires a thorough assessment of various factors, including the working medium, operating conditions, seal form, and installation type. Paramount among these considerations is ensuring compatibility with the working medium and adherence to pressure and temperature requirements to uphold effective sealing performance.

(1) Working Medium and Operating Conditions

When selecting O-ring material, prioritize compatibility with the working medium. Consider the seal’s exposure to pressure, temperature fluctuations, continuous operation duration, and operating cycles. Additionally, in rotating applications, account for temperature elevation due to frictional heat. Different sealing materials exhibit distinct physical and chemical properties, necessitating careful evaluation based on the application’s requirements.

(2) Seal Form

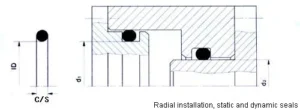

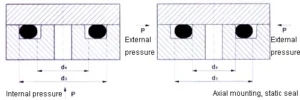

O-ring selection varies based on the type of load and seal form. Classify seals into static and dynamic categories based on load, and consider hole seals, shaft seals, and rotary shaft seals based on usage. For radial installation, ensure minimal deviation between the O-ring diameter and the seal diameter (d2) for shaft seals, and maintain equal or slightly smaller dimensions than the groove inner diameter (d1) for hole seals.

In axial installations, consider the direction of pressure. For internal pressure, opt for an O-ring outer diameter approximately 1 to 2% larger than the groove outer diameter (d3), while for external pressure, choose an O-ring inner diameter approximately 1 to 3% smaller than the groove inner diameter (d4).

By meticulously assessing these factors, engineers can make informed decisions when selecting O-ring materials, ensuring optimal performance and longevity in diverse sealing applications.

4. Critical Performance Parameters

Key parameters like O-ring hardness, extrusion gap, and compression permanent deformation significantly impact sealing efficacy. Hardness dictates compression and extrusion tolerance, while excessive deformation can compromise functionality. Maintaining optimal pre-compression, stretching, and compression levels is essential for both static and dynamic seals.

(1) O-Ring Hardness

The hardness of O-ring material is pivotal in sealing performance. It dictates compression and extrusion tolerance, influencing the sealing effectiveness. Shore A70 nitrile rubber is commonly used due to its versatility and compatibility with various conditions.

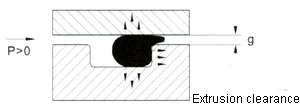

(2) Extrusion Gap

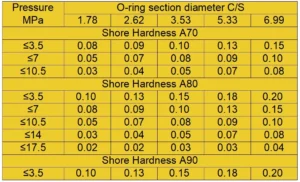

The maximum allowable extrusion clearance (gmax) is influenced by system pressure, O-ring cross-section diameter, and material hardness. Higher working pressures necessitate smaller extrusion clearances to prevent O-ring extrusion or damage.

(3) Compression Permanent Deformation

Evaluation of O-ring sealing performance of another indicator that the compression permanent deformation of the selected material. Under pressure, as an elastic element of the O-ring, resulting in elastic deformation, with increasing pressure, there will be permanent plastic deformation. Compression permanent deformation d can be determined by the following formula:

b0-b2

d=—–×100%

b0-b1

Where: b0-original thickness (i.e. section diameter W)

b1-Thickness in compression

b2-Thickness after release

Normally, in order to prevent permanent plastic deformation, the maximum allowable compression of O-rings is about 30% in static seals and 20% in dynamic seals.

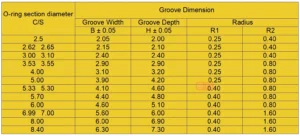

Table 2 Maximum allowable extrusion gap gmax

※ When the pressure exceeds 5MPa, the use of retaining rings is recommended.

※ For static seal applications, the recommended fit is H7/g6.

(4)Pre-compression

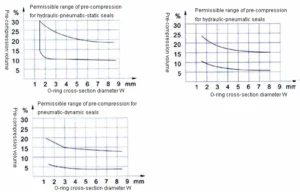

Pre-compression, an initial compression amount reserved during installation, is crucial for sealing performance. Optimal pre-compression levels vary based on application, typically ranging from 15-30% for static seals and 9-25% for dynamic seals.

This can be selected by referring to the following chart.

(5) Stretching and Compression

O-rings undergo stretching or compression during installation, impacting their cross-section diameter. Excessive stretching or compression can compromise sealing effectiveness. For hole seals, tension is preferred, with a maximum allowable tension of 6%, while for shaft seals, compression along the circumference is optimal, with a maximum allowable compression of 3%.

(6) O-Rings used as Rotary Shaft Seals

O-ring can also be used as a low-speed rotary movement and a short operating cycle of the rotary shaft seal. When the circumferential speed is less than 0.5m / s, O-ring selection can be based on normal design standards; when the circumferential speed is greater than 0.5m / s, we must take into account the elongation of the rubber ring will be contracted after the heat of the phenomenon, so the choice of sealing ring so that the inner diameter of the shaft diameter than it is sealed by about 2%, the above phenomenon can be avoided.

Seal ring installed in the groove, resulting in radial compression of the seal ring, O-ring ring in the groove to form a trace corrugated, thus improving the lubrication conditions.

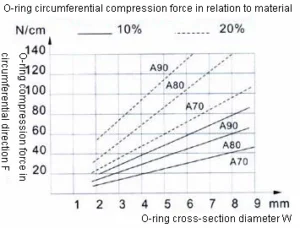

(7) Installation Compression Force

Installation compression force correlates with initial compression and material hardness. Estimating the total force required for installation involves considering the unit compression force per centimeter of the seal circumference and cross-section diameter, tailored to specific installation requirements.

Understanding and managing these critical parameters are essential for achieving effective sealing performance and ensuring O-ring reliability in diverse applications.

5. O-ring installation design

Proper installation design plays a pivotal role in O-ring performance. Triangular, rectangular, and trapezoidal groove configurations offer varied application suitability, with precise groove processing and surface finish ensuring optimal sealing integrity. Chamfering edges and deburring transition holes are vital to prevent damage during installation.

O-ring installed in the groove, it should be allowed to have a certain expansion space. Usually, the allowable expansion rate in the static seal is about 15%, in the dynamic seal is about 8%. For different types of grooves, the scope of application varies.

(1) There are three commonly used forms of grooves

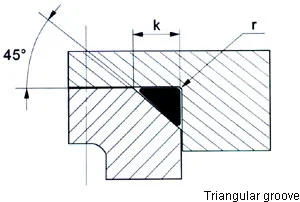

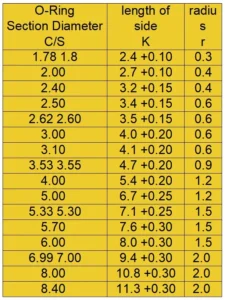

a. Triangular groove

Commonly used for seals on flanges and end caps. The disadvantages are that it is more difficult to manufacture and there is very little space for the O-ring to expand.

Triangular groove installation form (unit: mm)

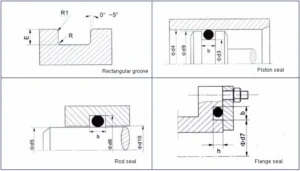

b. Rectangular groove

Widely used in a variety of applications. When a retaining ring is not required, it can also be made with an inclined side (<5°).

c. Trapezoidal groove

Recommended only for special applications where the O-ring cross-section diameter is greater than 2.5 mm. For example, a trapezoidal groove can be considered to keep the O-ring mounted at the top.

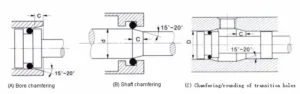

(2) local structural design

Because the O-ring in the installation of extrusion, in order to avoid damage to the hole end or shaft end must be processed into 15 ° ~ 20 ° chamfer, and the edges should be chamfered and deburred. If the O-ring is to be installed through a transverse hole, the transition hole must also be chamfered or rounded.

Table: Minimum length of chamfer Cmin Unit: mm

![]()

Chamfering surface roughness: Rz ≤ 4.0 μm Ra ≤ 0.8 μm

(3) Groove processing accuracy and surface requirements

Usually the sealed surface and groove surface does not allow the existence of small grooves, scratches, pits, concentric or spiral processing marks.

For the dynamic fit, the surface requirements are higher than the static fit.

Table: Surface finish

6. Installation of O-Rings

When installing O-rings, meticulous attention to detail is essential to ensure optimal sealing performance. Here are key considerations to bear in mind during installation:

(1) Chamfer and Deburr Edges

Prior to installation, chamfer or chamfer blunt the edges and deburr transition holes to prevent damage to the O-ring and ensure a smooth fit.

(2) Inspect Sealed Surface

Thoroughly examine the sealed surface for any defects or irregularities that could compromise the sealing integrity.

(3) Remove Machining Residues

Eliminate all machining residues from the installation area to prevent contamination and maintain a clean environment for the O-ring.

(4) Protect Threads

Utilize protective sleeves to shield threads along the installation path, preventing sharp corners from inadvertently scratching or damaging the O-ring.

(5) Apply Lubricating Grease

Facilitate installation by applying lubricating grease to the O-ring installation surface, easing friction and ensuring a snug fit.

(6) Use Tools Effectively

When installing manually, avoid sharp tools that may puncture or damage the O-ring. Instead, utilize tools effectively to prevent twisting and ensure proper alignment.

(7) Avoid Excessive Stretching

Prohibit excessive stretching of the O-ring during installation, as this can compromise its elasticity and sealing effectiveness.

(8) Handle Sealing Tape with Care

O-rings made of sealing tape should not be stretched at their joints to prevent weakening or damage.

(9) Prepare for Automatic Installation

Adequate preparation is crucial for automatic installation. Consider coating the O-ring surface with molybdenum and graphite, talcum powder, or PTFE coating to facilitate smooth installation and enhance sealing performance.

By adhering to these installation guidelines, you can ensure the proper fit and functionality of O-rings, promoting reliable sealing in various applications.

7. Storage and Maintenance Guidelines

O-rings, often designated as spare parts for prolonged periods, demand meticulous storage and maintenance protocols to safeguard their physical and chemical integrity, thereby preventing elastomer degradation.

To shield O-rings from adverse external influences and preserve their pristine condition, adhere to the following guidelines during storage:

(1) Store in a Dry Environment

Ensure O-rings are stored in a dry location to prevent moisture infiltration, which can compromise their elasticity and sealing performance.

(2) Maintain Optimal Temperature

Store O-rings within a temperature range of +5°C to +25°C, steering clear of direct exposure to heat sources. Extreme temperatures can distort the elastomer structure, leading to diminished functionality.

(3) Shield from Sunlight and Neon Light

Shield O-rings from direct exposure to sunlight and neon light to thwart UV-induced degradation, which can accelerate material breakdown and reduce longevity.

(4) Utilize Original Packaging or Airtight Containers

Store O-rings in their original packaging or airtight containers to mitigate the risk of oxidation. Exposure to oxygen over time can deteriorate the elastomer, compromising its sealing properties.

(5) Avoid Harmful Gas Sources

Keep O-rings away from sources of harmful gases, such as ozone, to prevent elastomer damage. Chemical exposure can initiate material degradation, jeopardizing sealing effectiveness.

By diligently observing these storage and maintenance guidelines, you can extend the lifespan of O-rings and uphold their sealing efficacy, ensuring reliable performance when deployed in critical applications.

By understanding O-ring characteristics, selecting appropriate materials, implementing precise installation designs, and adhering to maintenance protocols, users can maximize sealing efficiency and longevity. This comprehensive guide equips professionals with the knowledge needed to leverage O-rings effectively across diverse applications.