The piston of the pump truck is in direct contact with concrete, requiring sealing and abrasion resistance. When we find that the water in the tank is muddy or there is concrete, we should realize that the piston may be seriously worn. We need to check the piston. If the piston is worn, we need to replace it in time. So as not to strain the concrete cylinder. Each pump manufacturer piston replacement is much the same. We take the zoom-lion pump truck as an example.

1. The structure of the piston is shown below.

We need to replace the piston head and guide sleeve.

2. Preparation

Get the water and the stuff out of the tank.

3. Dis-assembly steps

(1) Remove the limit sleeve and pressure plate, as shown in the figure below.

(2) Close the U-shaped valve at the end of the oil cylinder and rotate it to be perpendicular to the oil cylinder, as shown in the figure below.

(3) Select the panel for face control and return the piston to the water tank by manual inching.

(4) Next, disassemble the piston with hexagon socket and crescent wrench (these tools are generally available on the vehicle. Please be sure to press the emergency stop button when disassembling )

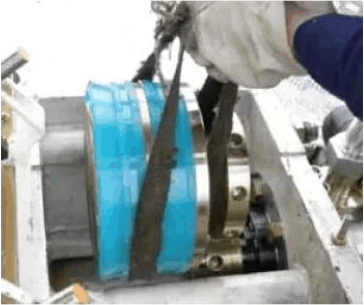

(5) Remove the piston body with a rope or other tools after completion of disassembly and complete dis-assembly.

4. Installation steps

(1) To facilitate installation, grease the piston before installation. Use the rope to lower the piston into the tank. Align the cylinder flange with the piston flange

(2) Move the oil cylinder slightly, push the piston to be replaced into a small part of the concrete cylinder, and align the flange connecting screw hole with the crescent wrench.

(3) Screw on the bolts once in order. After the first tightening, -must be tightened for the second time

(4) Inching repeatedly to make the piston and concrete cylinder fit better after tightening.

(5) Open the U-valve that has been closed during removal.

5. Matters needing attention

(1) Be sure to confirm the shutdown.

(2) Do not extend your hand into the concrete cylinder during operation to avoid danger.

(3) Must use rope or other tools, avoid direct hand to take when extracting piston.